Murata Noise Correction - Ameliorating Sensor Malfunction

Sensors are key in the Internet of Things (IoT) devices and self-driving vehicles, and their use in a range of products is only expected to grow. Noise suppression is both important and essential for various types of sensors because serious accidents could occur if sensors do not correctly transmit the sensed data. Murata researched malfunction mechanisms and noise suppression methods, using one-chip type sensors (digital output type) as an example.Mechanisms in which noise causes sensor malfunctions

One-chip sensors mainly consist of three types of lines: signal, power, and GND. In addition, communication is achieved using multiple signal lines such as clock and data. Murata examined the effects when noise is applied to the various lines.

Types of Signal

Application of noise to digital signal lines

An example of a malfunction where communication cannot be performed correctly is when noise is applied to digital signal lines and produces an incorrect judgment the level has exceeded the high threshold value or has fallen below the low threshold value.

Murata actually introduced noise to the digital signal lines of a particular accelerometer for evaluation and confirmed the malfunction where the communication stopped.

Applied Noise to Digital Lines Diagram

Application of noise to power lines

The analog front-end includes amplifier and A/D conversion circuits. When the power supplies of these circuits fluctuate and the circuits do not operate correctly, a malfunction may occur when abnormal values are produced.

Murata introduced noise to the power line of an accelerometer for evaluation and confirmed the malfunction in which the output was disrupted.

Applied Noise to Power Lines Diagram

Key points of sensor noise countermeasures

These are the conditions sought in filters used as countermeasures against noise in sensors:

1. Pass the power supply and the signals required for operation

2. Block the noise that causes malfunctions

Single-chip type sensors are available in a range of types and product names, but there is no large differences in the filters used as noise countermeasures.

This is because the two conditions sought in a filter are common to any sensor.

1. Pass the power supply and the signals required for operation

→ Single-chip type sensors have standardized interfaces (IC pins)

2. Block the impressed noise that causes malfunctions

→ The specifications of the impressed noise are standardized with an immunity test

Mounting position of the filter

Murata determined the filter needs to be mounted in the vicinity of the sensor to be effective.

Power line noise countermeasures

Filters with a high insertion loss over a wide bandwidth, from low frequencies to high frequencies, are ideally suited for use in power line noise countermeasures.

Countermeasures that use only capacitors will need a capacitor with a large capacitance value that covers the low-frequency side as well as a low ESL capacitor for obtaining a high-frequency insertion loss.

Combining capacitors and an inductor offers the advantage of a notable increase in insertion loss. Surpassing the use of an inductor, a more effective filter against noise can be obtained by arranging sufficient capacitance at the sensor side in a multi-level configuration.

Power Line Noise Countermeasures Diagram

Signal line noise countermeasures

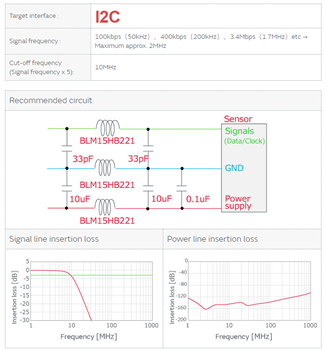

Noise countermeasures for (data/clock) signal lines require a filter design with low insertion loss at the signal frequencies that should be passed.

Countermeasures using only capacitors are possible when noise levels are small or when the frequencies of the signal and the noise are separated. But when the signal frequency and the noise frequency are close, it becomes necessary to configure filters with sharp insertion loss characteristics by combining inductors and capacitors.

Signal line noise countermeasures Diagram

Key points when using inductors

When an inductor is inserted in a specific line only, conversion to normal mode (a potential difference) occurs and the line becomes unbalanced. This increases the likelihood of malfunctions getting worse. When inserting inductors, Murata determined it is important the same part number is used in all of the lines. Note: Ferrite beads, an inductor type filter, not only block noise with high impedance but also absorb noise energy as a loss by the ferrite, so higher noise countermeasure effectiveness can be expected.

Countermeasure examples

Examples of power supply line noise countermeasures

Irregularities (output errors) of the sensor output value were generated as the effects of noise on the power supply lines of the sensor. The noise level injected onto the power supply line was kept constant and the size of the output error before and after the use of the countermeasure was examined.

Because malfunction of the sensor output value is attributable to the normal mode noise of the power supply lines, four low-ESL capacitors of 0.1µF were inserted in the vicinity of the sensor.

This action resulted in the suppression of the output error of the sensor to less than 1%.

When further noise countermeasures are required, as mentioned, inductors and capacitors can be configured into a Pi-type filter.

Power Supply Line Noise Countermeasures Example Diagram

Examples of signal line noise countermeasures

The communication of the sensor may stop due to the effect of the noise on the signal lines of the sensor. The injected noise level was increased, and the limit level for proper operation (when malfunctioning did not occur) was examined.

• Initial: Resistance to malfunctioning differs greatly with frequency. (In this example, resistance is low at 100MHz and 250MHz.)

• Countermeasure 1: Addition of capacitors improves resistance to malfunctioning at 100MHz and 250MHz.

• Countermeasure 2: A configuration of ferrite beads and capacitors improves resistance to malfunctioning at 200MHz and 250MHz.

• Countermeasure 3: To obtain a balance, a Pi-type filter is configured for the power supply line and ferrite beads are added to the ground (GND) line. This improves resistance to malfunctioning across all frequency ranges.

By putting Countermeasure 3 (recommended circuit) into practice, it was confirmed noise resistance became favorable across the entire frequency bandwidth.

Signal line noise countermeasures Example Diagram

Community Forum

Murata Community Forum provides searchable content with various discussion topics, popular blogs, and articles. The Murata broad market support team holds regular reviews to discuss open issues, allowing inquiries to be answered in a timely manner. The forum content is freely accessible to the public. However, users must log in to post questions or answers. Registration is free of charge.